In today’s construction and design landscape, energy efficiency, aesthetics, and long-term durability are no longer optional—they’re essential. That’s why builders and architects are increasingly turning to modern wall systems (including brick pattern metal insulated wall panels) that combine classic design with high performance. Among the most innovative choices available, certain architectural wall finishes are emerging as powerful solutions for a wide variety of building types.

Today let’s try to explore the top seven building categories where modern wall finishes with the appearance of traditional masonry—but with far superior performance—are making a big impact.

Table of Contents

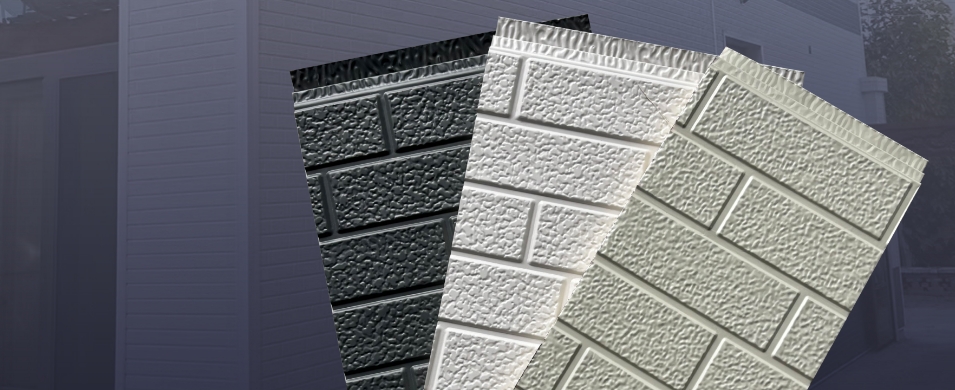

A Closer Look at Advanced Brick-Texture Wall Systems

While traditional brick exteriors have long been associated with durability and elegance, their drawbacks—such as weight, labor intensity, and limited insulation—are becoming harder to overlook in modern construction. That’s where new-generation wall systems,PU insulated metal panels, with masonry-like appearances offer a breakthrough. Engineered to replicate the charm of real brick while delivering advanced thermal performance, these systems combine multiple building layers into one integrated panel. The result is a lightweight yet structurally strong surface that speeds up construction while reducing long-term energy costs.

Each panel typically consists of three primary layers: an exterior metal skin embossed with realistic texture and pre-finished in weather-resistant coatings; a high-density rigid foam core that delivers excellent PU foam thermal insulation; and an interior aluminum foil paper backing that reinforces stability and simplifies installation. This composite structure not only mimics the visual depth of brickwork but also outperforms traditional materials in energy conservation, moisture control, and fire resistance.

In terms of size and practicality, standard panel widths typically fall between 383 mm and 400 mm, with lengths ranging from 2000 mm to 6000 mm, and a core thickness of approximately 16–20 mm. This sizing makes them ideal for covering large wall surfaces efficiently while remaining easy to handle and install. The panels’ closed-cell insulating core enhances thermal resistance, often achieving R-values from R-13 to R-21, helping meet or exceed modern energy codes.

Versatility in Application and Design

One of the most notable advantages of brick pattern Metal insulated wall panel is its adaptability across architectural styles and climates. On-site, contractors benefit from a precision interlocking joint system that ensures tight seams, reduces thermal bridging, and minimizes water penetration—all without the need for wet trades or heavy machinery.

Functionally, these systems offer more than surface appeal. They enhance thermal insulation, support sound attenuation, and deliver fire-retardant properties, making them suitable for everything from residential housing to large public facilities. The metal outer surface resists UV degradation, surface impact, and corrosion, making it ideal for both coastal regions and urban environments.

Aesthetically, the brick-texture finish comes in a range of color tones and grout styles, allowing builders to match regional architectural traditions or corporate branding. Because of the decorative insulated wall panel’s dimensional stability and fade-resistant coatings, buildings maintain their visual appeal for years with minimal maintenance.

Top 7 Building Types That Benefit from Brick-Pattern Metal Insulated Wall Panels

1. Residential Housing Developments

Homeowners appreciate the visual appeal of brick textures, but traditional masonry comes with high costs, complex installation, and limited insulation performance. Newer wall finishes, that is brick-embossed insulated metal wall panels mimic the classic look while drastically improving energy performance and reducing heating and cooling costs. Developers also benefit from quick installation and reduced labor requirements.

2. Schools and Educational Facilities

Schools have specific demands for safety, cost-efficiency, and longevity. Educational buildings are often large and complex, with wide exterior walls exposed to varying weather conditions. Using advanced modular wall solutions ,i.e. brick-look insulated metal wall panels helps reduce overall energy bills and keeps interior environments more comfortable year-round—critical for student learning conditions. Their impact-resistant surfaces can withstand daily wear and tear, graffiti, and environmental stress without frequent maintenance.

3. Healthcare Facilities

Hospitals, clinics, and rehabilitation centers demand materials that offer hygiene, safety, and energy efficiency. In many regions, compliance with energy codes and building safety standards is strict. Wall systems engineered with insulating cores and durable outer surfaces are ideal in this context. They help regulate interior temperature, which is crucial for patient comfort and equipment functionality. Additionally, these systems offer outstanding fire resistance and mold prevention—key concerns in healthcare design.

4. Retail Stores and Commercial Complexes

For commercial properties, first impressions matter. Exterior walls need to reflect the brand’s image while remaining cost-effective to maintain. Whether it’s a shopping mall, standalone retail store, or franchise chain, a clean, professional appearance must be balanced with durability and efficiency.The latest generation of exterior PU metal siding excels in these environments. With pre-finished surfaces, fade-resistant coatings, and natural-looking finishes, they eliminate the need for repainting or constant upkeep.

5. Hospitality and Hotel Buildings

Hotels and resorts need their façades to look inviting and timeless while offering long-lasting protection from the elements. Especially in regions with high humidity or large temperature variations, traditional masonry can crack, fade, or even become unsafe. For hotel developers, this results in lower lifetime maintenance costs, fewer repairs, and greater energy savings. The brick-pattern design adaptability allows them to match local architecture while upgrading the performance behind the walls.

6. Industrial and Warehouse Facilities

Industrial buildings often prioritize function over form—but in recent years, companies are rethinking how even warehouses and manufacturing sites appear to clients and employees. An upgraded exterior is also a smart way to reflect a commitment to sustainability and modern operations.PU insulated wall cladding systems provide the durability that harsh industrial environments require, while also dramatically reducing internal temperature fluctuations. This minimizes energy costs and protects temperature-sensitive goods or equipment.

7. Modular and Prefabricated Buildings

The rise of off-site construction and modular building solutions is transforming how structures are designed and assembled. Wall systems that combine lightweight profiles with built-in insulation and easy interlocking mechanisms are in high demand.These new brick pattern PU insulated wall cladding surfaces offer fast deployment without compromising appearance or functionality. In fact, their versatility and clean lines make them ideal for temporary shelters, pop-up retail units, site offices, and container-based dwellings.

Performance Highlights and Key Advantages

What sets this new generation of decorative insulated wall panels apart is their multi-functionality. These aren’t just decorative elements—they’re engineered for performance.

- Thermal Efficiency: High-density insulation cores improve energy ratings and help buildings meet stringent codes.

- Weather Resistance: Protective coatings and sealed joints keep water, air, and heat out.

- Fire Safety: Many of these panels offer high fire ratings, which is especially important in public buildings.

- Noise Control: Improved acoustic insulation reduces sound transmission, creating quieter interiors.

- Design Flexibility: A wide range of surface textures, colors, and profiles allows architects to customize designs without added engineering complexity.

Why PU Insulated Wall Panel Matters?

In the age of green building, architects and builders must think not just about initial appearance—but lifecycle cost and environmental impact. Wall systems (IND facade panel) that integrate insulation, moisture barriers, and durable surfaces help reduce carbon footprints over time.

Less maintenance means fewer resources spent on repairs, and better thermal performance translates to reduced energy consumption.

Additionally, many modern systems use recyclable materials and can contribute toward LEED certification or other sustainability targets.

Whether you’re designing a school, outfitting a retail chain, or launching a residential development, investing in high-performance wall panels with timeless visual appeal is a smart decision. These innovative systems (Decorative insulated wall panels) offer the best of both worlds—classic aesthetics and advanced technology—allowing buildings to stand out visually while performing reliably for decades.

If you’re looking for metal wall cladding that works as hard as the people inside the building, it’s time to consider a solution that does more than just look good.

Specifications of Decorative PU Wall Sandwich Panels

Decorative PU wall sandwich panels represent a revolutionary approach to modern construction, combining aesthetics with practicality. These panels boast a range of specifications that make them an attractive choice for a variety of applications:

1. Core Material: At the heart of decorative PU wall sandwich panels lies a core material made of polyurethane foam. This material is prized for its exceptional thermal insulation properties, helping to maintain comfortable indoor temperatures while reducing energy consumption. Additionally, polyurethane foam provides sound insulation, minimizing noise transmission and creating quieter indoor environments.

2. Exterior Finish: The exterior surface of decorative metal siding panels is adorned with a variety of finishes, ranging from sleek metallic coatings to textured patterns and vibrant colors. This versatility allows architects and designers to achieve their desired aesthetic vision, whether it be modern and minimalist or ornate and intricate.

3. Panel Dimensions: Decorative PU wall sandwich panels come in a range of dimensions to suit different project requirements. Standard panel widths are 383mm and 400mm, with lengths customizable to fit specific building dimensions. The thickness of the panels can vary as well, with options typically ranging from 10mm to 25mm, providing flexibility in insulation and structural performance.

4. Lightweight Construction: Despite their robust insulation properties, decorative PU wall sandwich panels are remarkably lightweight. This characteristic facilitates easy handling and installation, reducing labor costs and construction time. The lightweight nature of the panels also places less stress on building structures, making them suitable for both new construction and retrofit projects.

5. Fire Resistance and Durability: Decorative PU wall sandwich panels are engineered to meet stringent fire safety standards, ensuring the protection of occupants and assets. Additionally, these panels are highly durable, capable of withstanding environmental factors such as moisture, UV exposure, and temperature fluctuations. This durability contributes to the longevity of buildings and reduces maintenance requirements over time.

In summary, decorative PU wall sandwich panels offer a combination of thermal insulation, aesthetic appeal, ease of installation, and durability, making them a versatile choice for a wide range of construction projects across residential, commercial, and industrial sectors.