Exterior Metal Carved Boards:Aesthetic Wall Cladding for Insulation & Decoration

In today’s rapidly evolving construction and design industry, building envelope materials are under increasing pressure to perform both functionally and aesthetically. Architects and project developers are constantly searching for solutions that combine durability, thermal insulation, fire resistance, and elegant exterior finishes—all within tight budgets and shorter timelines.

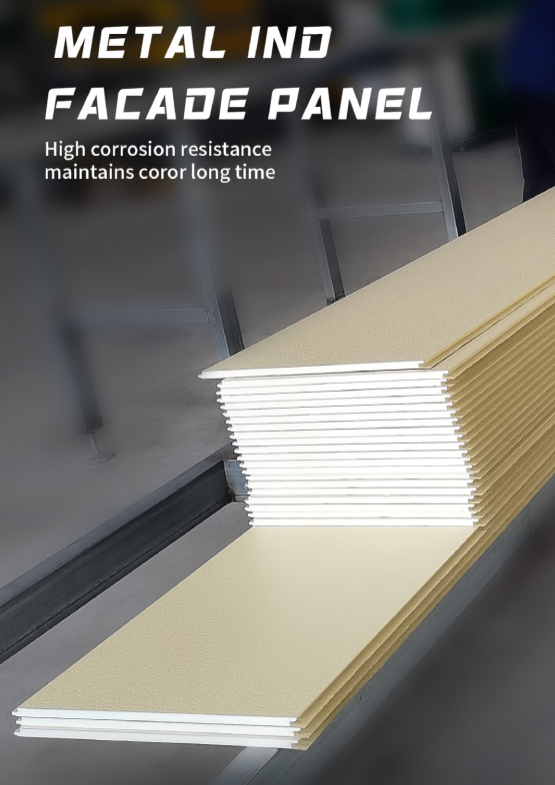

One material that has emerged as a frontrunner in this space is the exterior metal carved board, also known as a PU metal carving wall panel. This next-generation IND facade panels seamlessly integrates energy-saving insulation with architectural versatility, making it a preferred solution for residential, commercial, and industrial exterior walls.

Table of Contents

What is an Exterior Metal Carved Board?

An exterior metal carving panel is a lightweight, prefabricated wall cladding system composed of three essential layers:

- Surface Layer: High-quality Alu-zinc pre-painted steel, 0.25 mm thick. This layer is embossed with various textures such as brick, stone, or wood patterns to simulate natural finishes.

- Core Layer: Rigid polyurethane foam insulation (PU foam), 16 mm thick, with a density of 40 kg/m³. It serves as the thermal and acoustic barrier.

- Back Layer: Reinforced aluminum foil paper, which improves moisture and heat resistance while adding structural stability.

This sandwich-like structure is engineered to offer exterior wall insulation decoration, excellent energy efficiency and long-term weather protection while enhancing exterior aesthetics.

Key Technical Parameters

Below is a summary of the typical technical specifications of a standard PU metal carving wall panel:

| Specification | Value |

|---|---|

| Panel Width | 380 mm |

| Effective Width | 375 mm |

| Panel Length | Customizable (typically ≤ 6000 mm) |

| Surface Material | 0.25 mm Alu-zinc steel |

| Core Material | Rigid PU foam (40 kg/m³) |

| Core Thickness | 16 mm |

| Back Material | Aluminum foil |

| Thermal Conductivity | ≤ 0.022 W/m·K |

| Fire Rating | B1/B2 (Optional) |

| Water Absorption | ≤ 0.1% |

| Weight | ≈ 3.7–4.0 kg/m² |

| Sound Insulation | ≥ 29 dB |

These parameters make the exterior wall siding panel suitable for various climate zones, from humid coastal areas to dry, high-temperature inland regions.

Functions & Performance Benefits

The metal carved wall board isn’t just a decorative element; it’s a multi-functional cladding solution. Here are the key benefits:

1. Thermal Insulation

The rigid PU foam core ensures outstanding heat retention in cold seasons and thermal resistance in summer, reducing indoor HVAC consumption and lowering energy bills.

2. Waterproof and Weatherproof

Thanks to its closed-cell polyurethane core and overlapping joint design, the panel provides high resistance to rain, snow, and wind, protecting the building envelope from moisture ingress and corrosion.

3. Fire Retardant

With optional B1-grade fireproofing, the exterior metal carved wall board meets international safety standards for flame resistance, making it safe for both residential and commercial applications.

4. Noise Reduction

The PU foam core also acts as an effective sound barrier, reducing external noise by up to 30 decibels—ideal for buildings in urban or high-traffic environments.

5. Lightweight and Easy to Install

Weighing only around 4 kg per square meter, the panels are easy to transport and handle. Installation can be completed with minimal tools using embedded locking systems, reducing labor costs and time on site.

6. Aesthetic Flexibility

From brick and stone to timber-like finishes, the PU metal carving wall panel offers dozens of design options. Whether you’re aiming for rustic charm, modern minimalism, or a classical facade, there’s a carved metal panel to match your vision.

Applications Across Industries

Due to its adaptability and performance, exterior wall siding panels are being increasingly used across a wide range of building types:

● Residential Housing

Whether it’s single-family homes or multi-unit housing projects, these panels offer both insulation and curb appeal, especially in prefab and modular home construction.

● Commercial Buildings

Shopping malls, office complexes, showrooms, and business parks benefit from the panels’ clean appearance and quick installation.

● Industrial Facilities

Warehouses, logistics centers, and factory buildings require both thermal performance and cost-effective solutions. The metal carved wall board meets both requirements efficiently.

● Public Infrastructure

Schools, hospitals, government buildings, and even temporary structures like mobile clinics and disaster relief shelters increasingly adopt these panels for fast deployment and low maintenance.

Sustainability & Eco-Friendliness

An often-overlooked advantage of metal carved board is their contribution to green building standards:

- Energy saving: Superior insulation lowers carbon emissions by reducing energy consumption.

- Recyclability: The steel and aluminum components are recyclable, reducing construction waste.

- Longevity: With a life expectancy of over 25 years, the panels reduce the need for frequent replacements and associated emissions.

Their use can contribute to green certification points in systems like LEED, BREEAM, or China’s Green Building Label.

Installation & Maintenance

The panels use a tongue-and-groove system or concealed fasteners that ensure seamless connections without visible screws. This not only enhances aesthetics but also minimizes thermal bridging. Panels can be cut to fit using standard tools and require no wet trades or curing time, allowing for year-round installation.

Maintenance is minimal. Routine cleaning with water and mild detergent is sufficient to keep the facade looking new. The pre-painted surface layer resists fading, rust, and chipping, even under extreme weather conditions.

Why Choose Exterior Metal Carved Board?

With urbanization accelerating and building codes tightening worldwide, developers and architects are under pressure to deliver structures that are cost-effective, energy-efficient, and architecturally compelling.

The pu metal carved board presents an all-in-one solution. It replaces the traditional multiple-layer wall systems—brick + insulation + plaster—into a single, pre-fabricated panel that is easy to install, easy to maintain, and beautiful to look at.

Whether you’re working on a new build, refurbishment, or prefabricated housing project, the PU metal carving wall panel offers a smart, sustainable, and stylish path forward.

Looking Ahead

As smart cities and green buildings continue to define the future of architecture, exterior metal carving panels will play a growing role in shaping our living and working environments. Their combination of functionality, visual impact, and sustainability make them a cornerstone material in modern façade engineering.

Interested in learning more or getting a sample? Contact us today and discover how metal carved wall boards can elevate your next project.

Specifications of Decorative PU Wall Sandwich Panels

Decorative PU wall sandwich panels represent a revolutionary approach to modern construction, combining aesthetics with practicality. These panels boast a range of specifications that make them an attractive choice for a variety of applications:

1. Core Material: At the heart of decorative PU wall sandwich panels lies a core material made of polyurethane foam. This material is prized for its exceptional thermal insulation properties, helping to maintain comfortable indoor temperatures while reducing energy consumption. Additionally, polyurethane foam provides sound insulation, minimizing noise transmission and creating quieter indoor environments.

2. Exterior Finish: The exterior surface of decorative metal siding panels is adorned with a variety of finishes, ranging from sleek metallic coatings to textured patterns and vibrant colors. This versatility allows architects and designers to achieve their desired aesthetic vision, whether it be modern and minimalist or ornate and intricate.

3. Panel Dimensions: Decorative PU wall sandwich panels come in a range of dimensions to suit different project requirements. Standard panel widths are 383mm and 400mm, with lengths customizable to fit specific building dimensions. The thickness of the panels can vary as well, with options typically ranging from 10mm to 25mm, providing flexibility in insulation and structural performance.

4. Lightweight Construction: Despite their robust insulation properties, decorative PU wall sandwich panels are remarkably lightweight. This characteristic facilitates easy handling and installation, reducing labor costs and construction time. The lightweight nature of the panels also places less stress on building structures, making them suitable for both new construction and retrofit projects.

5. Fire Resistance and Durability: Decorative PU wall sandwich panels are engineered to meet stringent fire safety standards, ensuring the protection of occupants and assets. Additionally, these panels are highly durable, capable of withstanding environmental factors such as moisture, UV exposure, and temperature fluctuations. This durability contributes to the longevity of buildings and reduces maintenance requirements over time.

In summary, decorative PU wall sandwich panels offer a combination of thermal insulation, aesthetic appeal, ease of installation, and durability, making them a versatile choice for a wide range of construction projects across residential, commercial, and industrial sectors.