A Comprehensive Guide to Installing and Maintaining Decorative PU Sandwich Panels for Walls

Decorative PU sandwich panels are a popular choice for both exterior and interior walls due to their durability, versatility, and aesthetic appeal. Produced from decorative pu sandwich panels productin line, these pu sandwich panels can be supplied in large quantities. Whether you’re renovating your home or designing a commercial space, understanding the installation process and proper maintenance techniques is essential to maximize the lifespan and performance of these panels. In this article, we’ll provide a step-by-step guide on installing decorative wall panels, along with tips for handling, cutting, fixing, and maintaining them.

Table of Contents

- Step-by-Step Installation Guide of Decorative PU Sandwich Panels:

- Tips for Proper Handling, Cutting, and Fixing:

- Maintenance Practices of PU Sandwich Panels on Exterior and Interior Walls

Step-by-Step Installation Guide of Decorative PU Sandwich Panels:

- Preparation: Before starting the installation process, ensure that the wall surface is clean, dry, and free from any debris or contaminants. Measure the area where the panels will be installed to determine the quantity needed.

- Panel Handling: Handle the panels with care to prevent any damage during transportation and installation. Use gloves to protect the panels from fingerprints and scratches. Avoid dragging or dropping the panels, as this can cause dents or dings.

- Cutting the Panels: Measure and mark the panels according to the dimensions of the wall. Use a fine-toothed saw or a utility knife to cut the panels to the required size. Take precise measurements to ensure a perfect fit.

- Fixing the Panels: Start by applying adhesive to the back of the panel or directly onto the wall surface. Press the panel firmly against the wall, ensuring proper alignment and spacing between panels. Use screws or nails to secure the panels in place, following the manufacturer’s guidelines for spacing and fastener placement.

- Sealing Joints: Seal the joints between panels using PU sealant or silicone caulk to prevent moisture infiltration and improve the overall appearance of the installation. Smooth out the sealant with a putty knife or caulking tool for a neat finish.

- Finishing Touches: Once all panels are installed, inspect the surface for any imperfections or gaps. Touch up any areas that require additional sealant or adhesive. Clean the panels with a mild detergent and water to remove any residue or marks.

Tips for Proper Handling, Cutting, and Fixing of Metal Siding Panels:

- Use the Right Tools: Invest in high-quality tools specifically designed for cutting and installing PU decorative wall panels. This will ensure clean cuts and secure fastening, minimizing the risk of damage to the panels.

- Work with Precision: Take accurate measurements and double-check the dimensions before cutting the panels. A small mistake can lead to misaligned panels and uneven seams, detracting from the overall appearance of the installation.

- Follow Manufacturer Guidelines: Refer to the manufacturer’s instructions and guidelines for proper handling, cutting, and fixing of the panels. Deviating from these recommendations can compromise the integrity and performance of the panels.

- Protective Gear: Wear appropriate safety gear, including gloves and safety goggles, when handling and cutting the panels to protect yourself from injury.

- Allow for Expansion and Contraction: Leave a small gap around the perimeter of the panels to accommodate thermal expansion and contraction. This will prevent buckling or warping of the panels over time.

Maintenance Practices of Decorative Wall Panels on Exterior and Interior Walls

- Regular Cleaning: Maintain the cleanliness of the panels by regularly wiping them down with a soft cloth or sponge dampened with water and mild detergent. Avoid using abrasive cleaners or harsh chemicals, as these can damage the surface finish.

- Inspect for Damage: Periodically inspect the metal siding panels for any signs of damage, such as cracks, dents, or loose fasteners. Promptly repair any damage to prevent further deterioration and ensure the longevity of the panels.

- Reapply Sealant: Check the seals around joints and edges for signs of wear or deterioration. Reapply PU sealant or silicone caulk as needed to maintain a watertight seal and prevent moisture infiltration.

- Protect from Harsh Elements: If installed outdoors, take precautions to protect the panels from exposure to harsh weather conditions, such as UV radiation, extreme temperatures, and moisture. Consider applying a protective coating or UV-resistant finish to enhance durability and longevity.

- Professional Maintenance Services: In some cases, it may be beneficial to enlist the services of a professional maintenance provider to perform routine inspections and maintenance tasks. They can identify potential issues early on and implement appropriate solutions to prolong the lifespan of the panels.

- Record Keeping: Keep detailed records of all maintenance activities performed on the panels, including dates, repairs, and any issues identified. This information can be valuable for tracking the condition of the panels over time and planning future maintenance efforts.

By following these guidelines for installation and maintenance, you can ensure the longevity and performance of decorative PU sandwich panels for both exterior and interior walls. Proper installation and maintenance are crucial for ensuring the longevity and performance of decorative PU sandwich panels for both exterior and interior walls. These step-by-step installation guide, implementing proper handling and fixing techniques, and adhering to recommended maintenance practices will ensure you to protect your investment and enjoy the benefits of these versatile and aesthetically pleasing panels for years to come. Remember to address any issues promptly and seek professional assistance when needed to maximize the lifespan and durability of your panels.

Specifications of Decorative PU Wall Sandwich Panels

Decorative PU wall sandwich panels represent a revolutionary approach to modern construction, combining aesthetics with practicality. These panels boast a range of specifications that make them an attractive choice for a variety of applications:

1. Core Material: At the heart of decorative PU wall sandwich panels lies a core material made of polyurethane foam. This material is prized for its exceptional thermal insulation properties, helping to maintain comfortable indoor temperatures while reducing energy consumption. Additionally, polyurethane foam provides sound insulation, minimizing noise transmission and creating quieter indoor environments.

2. Exterior Finish: The exterior surface of decorative PU wall sandwich panels is adorned with a variety of finishes, ranging from sleek metallic coatings to textured patterns and vibrant colors. This versatility allows architects and designers to achieve their desired aesthetic vision, whether it be modern and minimalist or ornate and intricate.

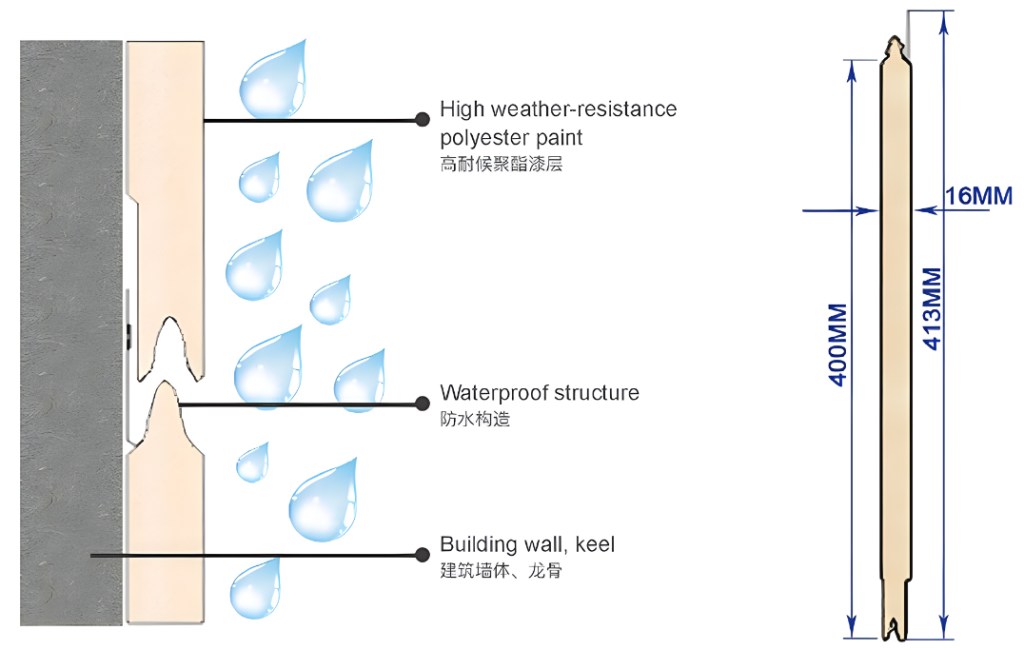

3. Panel Dimensions: Decorative PU wall sandwich panels come in a range of dimensions to suit different project requirements. Standard panel widths typically range from 383mm to 520mm, with lengths customizable to fit specific building dimensions. The thickness of the panels can vary as well, with options typically ranging from 10mm to 30mm, providing flexibility in insulation and structural performance.

4. Lightweight Construction: Despite their robust insulation properties, decorative PU wall sandwich panels are remarkably lightweight. This characteristic facilitates easy handling and installation, reducing labor costs and construction time. The lightweight nature of the panels also places less stress on building structures, making them suitable for both new construction and retrofit projects.

5. Fire Resistance and Durability: Decorative PU wall sandwich panels are engineered to meet stringent fire safety standards, ensuring the protection of occupants and assets. Additionally, these panels are highly durable, capable of withstanding environmental factors such as moisture, UV exposure, and temperature fluctuations. This durability contributes to the longevity of buildings and reduces maintenance requirements over time.

In summary, decorative PU wall sandwich panels offer a combination of thermal insulation, aesthetic appeal, ease of installation, and durability, making them a versatile choice for a wide range of construction projects across residential, commercial, and industrial sectors.

[…] ready, measuring carefully, and fastening securely. Check panels often and do upkeep, like adding sealants again and shielding them from bad weather. These steps help your panels stay useful and look nice for many […]

[…] measuring tape, I determine the exact length and width required for each panel. To avoid errors, I double-check all measurements before marking the panels. Following the manufacturer’s instructions ensures that the panels fit perfectly and perform as […]