Metal Insulated Wall Panels vs. PU Wall Cladding – What Should Architects Really Look For?

In today’s architecture and construction industries designers face growing pressure to create buildings that are not only visually appealing but also energy efficient cost effective and sustainable. One critical decision point in any building project is the selection of wall insulation and cladding materials. These materials directly impact the thermal performance aesthetic value and long term durability of the structure. As such the choice between different panel systems including the increasingly popular PU wall cladding or Metal Insulated Wall Panel has become a key consideration during the design phase.

Table of Contents

The Expanding Market of Wall Cladding Materials

Wall cladding has evolved beyond aesthetics. Modern designers, architects, and developers are increasingly prioritizing thermal insulation, durability, fire resistance, and ease of installation. The market today offers a variety of cladding types, including wood veneer, fiber cement, aluminum composite, HPL boards, and PU insulated wall panels. Among these, polyurethane-based systems—particularly PU wall panels and PU sandwich panels—are gaining popularity for their balance of performance and cost-efficiency.

Common Types of Wall Cladding Materials

| Material Type | Thermal Insulation | Fire Resistance | Weight | Lifespan |

|---|---|---|---|---|

| Fiber Cement | Medium | Good | Medium | 20–30 yrs |

| Aluminum Panel | Low | Medium | Light | 30+ yrs |

| Wood Veneer | Low | Poor | Light | 10–20 yrs |

| PU Wall Panel | Excellent | Excellent | Light | 30+ yrs |

Why PU Wall Cladding is Gaining Ground

PU insulated wall cladding, also known as polyurethane foam insulated wall cladding, integrates thermal efficiency, structural integrity, and surface decoration. It combines a metal outer layer—usually pre-coated steel or aluminum—with a rigid polyurethane foam core. This structure makes it not only strong and fire-resistant, but also exceptionally lightweight and energy-saving.

The decorative PU insulated wall panel is a high-performance exterior panel system. The polyurethane foam provides excellent thermal conductivity values, with a lambda as low as 0.022 W/m·K, making it an ideal choice for energy-efficient building envelopes. Surface finishes can be customized with different patterns such as brick, wood grain, or solid colors to meet architectural aesthetics. In addition to superior insulation, PU wall cladding offers weather resistance, corrosion protection, and easy installation due to tongue-and-groove or hidden fastener systems. These features make PU metal siding a popular solution in both residential and commercial applications.

Composition and Technical Specifications

| Layer | Description |

| Outer Face | Pre-painted galvanized steel or aluminum sheet |

| Core | Rigid polyurethane foam, CFC-free |

| Inner Face | Embossed aluminum foil or steel sheet |

| Thickness | 16mm, 20mm, 30mm, customizable |

| Panel Width | Standard 383mm or 400mm |

| Thermal Conductivity | ≤ 0.021 W/(m·K) |

| Fire Rating | B1/B2 grade (EN13501 or GB8624 standard) |

Comparing Standard PU Sandwich Panel vs IND Metal Siding Panel

While both options fall under the category of PU insulated siding panel, their applications and compositions differ significantly. The following table outlines their core similarities and distinctions:

| Feature | Standard PU Sandwich Panel | IND PU Metal Siding Panel |

| Insulation Core | Polyurethane foam | Polyurethane foam |

| Facing Materials | Color-coated steel (double) | Aluminum or PPGL on one side |

| Mounting Type | Tongue-and-groove or joint seam | Concealed interlocking seam |

| Decorative Surface | Flat, embossed, or corrugated | Brick, stone, or woodgrain finish |

| Installation Direction | Usually vertical | Horizontal or vertical |

| Usage Area | Industrial, cold room, warehouse | Residential, commercial façade |

| Panel Width | 950mm–1150mm | 383mm or 400mm |

| Aesthetic Appeal | Basic | Premium decorative appearance |

Considerations Designers Prioritize

1. Energy Efficiency

Designers often prioritize materials with low thermal conductivity. PU insulated wall panels, thanks to their rigid foam core, provide excellent thermal insulation, reducing energy consumption in both hot and cold climates.

2. Fire Safety

Safety regulations require façade materials to be fire-resistant. Most IND panel today meet B1 or B2 fire ratings, ensuring compliance with regional standards.

3. Durability and Maintenance

Metal insulated wall panels are preferred for their corrosion resistance and minimal maintenance. When combined with high-quality coatings, PU panels can last over 30 years.

4. Installation Efficiency

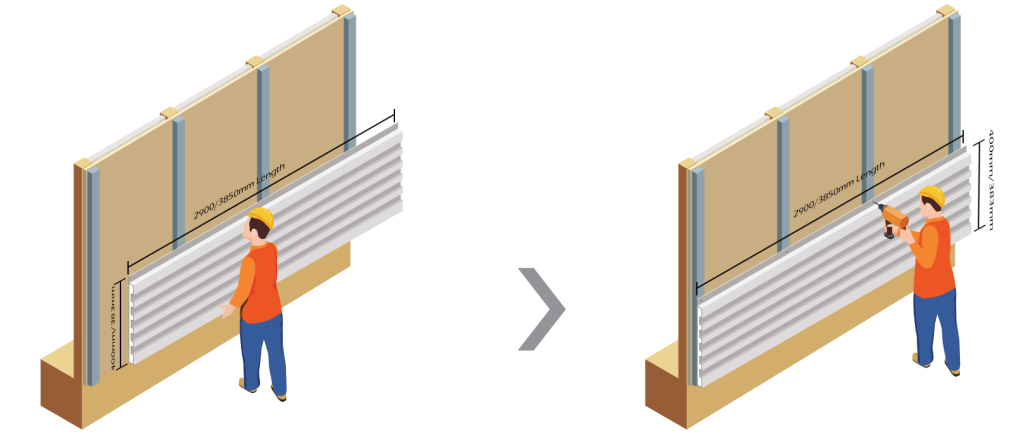

PU panels are lightweight and pre-formed, making installation faster and more cost-effective. IND panels go one step further with concealed fasteners and locking systems, enhancing aesthetics and safety.

5. Visual Design Requirements

Contemporary architecture demands both functionality and visual appeal. While regular PU sandwich panels offer limited design options, IND PU metal siding panels simulate real brick, stone, or woodgrain textures, giving buildings a luxurious finish.

Applications Across Industries

PU wall cladding and polyurethane insulated Wall Cladding panels are versatile and widely used in:

- Modern residential housing

- Prefabricated modular buildings

- Commercial and public architecture

- Hospitals, schools, and government facilities

- Cold storage or cleanroom facilities (for standard PU sandwich panels)

Future Outlook: Where Is PU Insulated Wall Cladding Headed?

With rising global energy costs and tighter building codes on thermal performance and fire safety, the demand for high-efficiency insulation panels is expected to surge. The global market for PU insulated siding panels is projected to grow steadily over the next decade, especially in regions with extreme climates.

IND panels, with their superior aesthetics and advanced fastening systems, are likely to dominate the decorative façade market. As architects and developers continue to merge beauty with performance, PU wall cladding will remain a go-to material in sustainable building practices.

Whether you’re designing a high-end residence or a large-scale public facility, choosing the right thermal cladding system is essential. Browse our catalog or contact us directly for a customized quote on PU insulated wall panel, Metal Siding Panel, or our signature IND PU Wall Cladding series. We’re here to help you build smarter and more beautifully.

Specifications of Decorative PU Wall Sandwich Panels

Decorative PU wall sandwich panels represent a revolutionary approach to modern construction, combining aesthetics with practicality. These panels boast a range of specifications that make them an attractive choice for a variety of applications:

1. Core Material: At the heart of decorative PU wall sandwich panels lies a core material made of polyurethane foam. This material is prized for its exceptional thermal insulation properties, helping to maintain comfortable indoor temperatures while reducing energy consumption. Additionally, polyurethane foam provides sound insulation, minimizing noise transmission and creating quieter indoor environments.

2. Exterior Finish: The exterior surface of decorative metal siding panels is adorned with a variety of finishes, ranging from sleek metallic coatings to textured patterns and vibrant colors. This versatility allows architects and designers to achieve their desired aesthetic vision, whether it be modern and minimalist or ornate and intricate.

3. Panel Dimensions: Decorative PU wall sandwich panels come in a range of dimensions to suit different project requirements. Standard panel widths are 383mm and 400mm, with lengths customizable to fit specific building dimensions. The thickness of the panels can vary as well, with options typically ranging from 10mm to 25mm, providing flexibility in insulation and structural performance.

4. Lightweight Construction: Despite their robust insulation properties, decorative PU wall sandwich panels are remarkably lightweight. This characteristic facilitates easy handling and installation, reducing labor costs and construction time. The lightweight nature of the panels also places less stress on building structures, making them suitable for both new construction and retrofit projects.

5. Fire Resistance and Durability: Decorative PU wall sandwich panels are engineered to meet stringent fire safety standards, ensuring the protection of occupants and assets. Additionally, these panels are highly durable, capable of withstanding environmental factors such as moisture, UV exposure, and temperature fluctuations. This durability contributes to the longevity of buildings and reduces maintenance requirements over time.

In summary, decorative PU wall sandwich panels offer a combination of thermal insulation, aesthetic appeal, ease of installation, and durability, making them a versatile choice for a wide range of construction projects across residential, commercial, and industrial sectors.

[…] screw hidden interlocking method, similar interlocking method as PU wall cladding not only improves aesthetics but also prevents water infiltration and enhances the panels’ wind […]