Metal Insulated Wall Panels: Superior Thermal Insulation Board Siding

Metal insulated wall panels have gained immense popularity in the construction industry due to their exceptional thermal insulation, durability, and energy efficiency. Among the most widely used metal insulated panels are PU Insulated Wall Panels and Rockwool Insulated Sandwich Panels. These panels, known aslo as IND panels (Insulation and Decoration Panel) offer a variety of benefits, making them ideal for commercial, industrial, and residential applications.

Materials and Composition

Table of Contents

PU Insulated Sandwich Panel

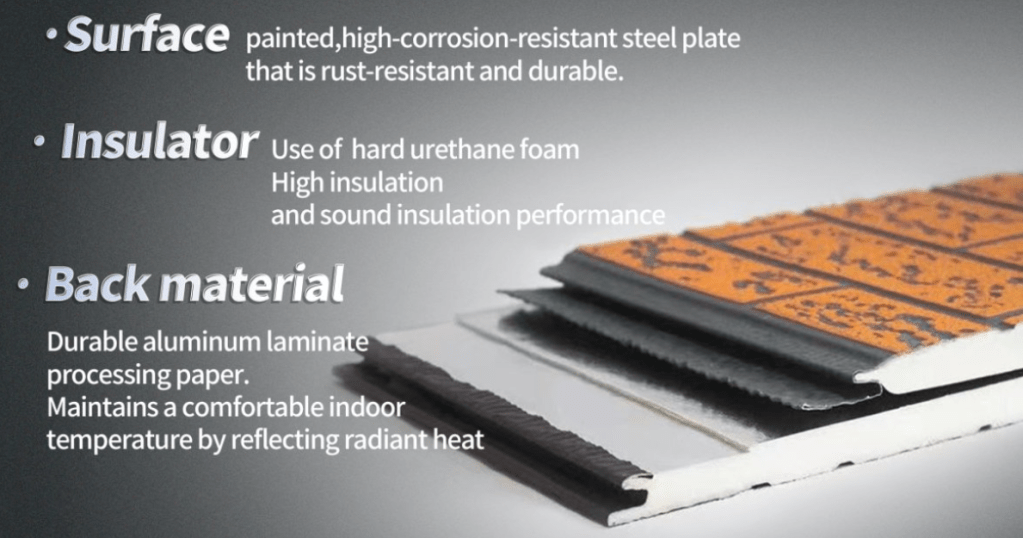

PU (Polyurethane) insulated wall panels are manufactured using high-quality materials, ensuring longevity and superior insulation properties. The composition includes:

- Surface Material: AZ100 galvalume color steel

- Core Material: High-rigid Polyurethane (PU) foam

- Back Material: Aluminum foil paper

- Dimensions: Width – 400mm, Thickness – 16mm, Length – 3800mm

Rockwool Insulated Sandwich Panel

Rockwool insulated sandwich panels are another excellent option for fire resistance and sound insulation. Their composition includes:

- Surface Material: AZ100 galvalume color steel

- Core Material: High-density Rock Wool or Mineral Wool

- Back Material: AZ100 galvalume color steel

- Dimensions: Width – 460mm, Thickness – 50mm, Length – 3800mm

Key Features of Metal Insulated Wall Panels

PU Insulated Metal Panels

- Superior Thermal Insulation: PU foam provides excellent thermal resistance, reducing heat transfer and energy costs.

- Lightweight and High Strength: Despite its low density, PU insulation offers outstanding strength and structural integrity.

- Moisture and Corrosion Resistance: The aluminum foil backing prevents moisture absorption, enhancing panel durability.

- Easy Installation: The lightweight design facilitates quick and hassle-free installation, reducing labor costs.

- Soundproofing: The closed-cell structure of PU foam helps in noise reduction, making it suitable for sound-sensitive environments.

- Energy Efficiency: Lower energy consumption contributes to reduced carbon footprints and operational savings.

Rockwool Insulated Sandwich Panels

- Exceptional Fire Resistance: Rockwool has a high melting point, making it highly fire-resistant and safe for various applications.

- Superior Sound Insulation: The dense fiber structure effectively reduces noise pollution, ideal for industrial and residential buildings.

- High Strength and Durability: The AZ100 galvalume color steel surface ensures long-term resistance against environmental damage.

- Water and Moisture Resistance: The non-hygroscopic nature of Rockwool prevents water absorption, preventing mold and fungal growth.

- Sustainability: Made from natural stone materials, Rockwool is an environmentally friendly insulation option.

- Enhanced Structural Integrity: Provides enhanced load-bearing capabilities, making it suitable for structural applications.

Applications of Metal Insulated Wall Panels

Both PU insulated wall panels and Rockwool insulated sandwich panels are used in a variety of industries, including:

- Cold Storage & Refrigeration: PU insulated panels are preferred for cold storage warehouses due to their high thermal resistance.

- Commercial and Industrial Buildings: Rockwool panels provide excellent fire safety, making them ideal for factories, workshops, and commercial centers.

- Prefabricated Structures: Both types of panels are used in modular buildings, site offices, and temporary structures due to their easy installation.

- Residential Applications: Homes benefit from their soundproofing, insulation, and durability.

- Agricultural and Livestock Buildings: Protects against extreme weather conditions and enhances energy efficiency.

- Cleanrooms & Medical Facilities: PU panels are widely used in cleanroom applications due to their low moisture absorption and hygiene benefits.

- Industrial Enclosures and Sound Barriers: Rockwool panels are frequently used in manufacturing plants to create soundproof partitions.

- Data Centers: PU panels help maintain controlled temperature environments crucial for server rooms.

Comparing PU and Rockwool Wall Sandwich Panels

| Feature | PU Insulated Wall Panel | Rockwool Insulated Wall Panel |

|---|---|---|

| Thermal Insulation | Excellent | Moderate |

| Fire Resistance | Moderate | Excellent |

| Soundproofing | Good | Excellent |

| Weight | Lightweight | Heavier |

| Moisture Resistance | Excellent | Moderate |

| Durability | High | High |

| Installation | Easy | Moderate |

| Cost | Moderate | Higher due to fire-resistant properties |

Why Choose Insulated Metal Wall Panels?

- Energy Efficiency: Reduced heating and cooling costs due to superior insulation properties.

- Cost-Effective: Lower maintenance and installation costs compared to traditional building materials.

- Long Lifespan: Highly durable, capable of withstanding extreme weather conditions.

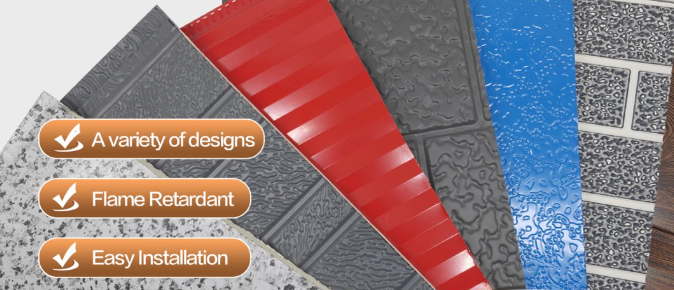

- Aesthetic Appeal: Available in various colors and finishes to enhance architectural designs.

- Eco-Friendly: Manufactured using recyclable materials, reducing environmental impact.

- Improved Building Safety: Fire-resistant properties of Rockwool panels enhance overall building security.

- Increased Property Value: Buildings with superior insulation and energy efficiency tend to have higher resale value.

- Regulatory Compliance: Meets energy efficiency and fire safety standards in various countries.

Conclusion

Metal insulated wall panels, whether PU or Rockwool insulated, offer unmatched performance in insulation, durability, and safety. With their energy-efficient properties, easy installation, and multiple applications, they are a preferred choice for modern construction projects. Whether you are looking for superior fire resistance, thermal insulation, or soundproofing, these thermal metal siding panels provide the perfect solution for various industries.

By choosing the right insulated panel based on your project’s needs, you ensure long-term cost savings, enhanced performance, and a safe, sustainable building environment.

Looking for high-quality insulated wall panels? Contact us today to learn more about our PU and Rockwool insulated panels for your next project!

Specifications of Decorative PU Wall Sandwich Panels

Decorative PU wall sandwich panels represent a revolutionary approach to modern construction, combining aesthetics with practicality. These panels boast a range of specifications that make them an attractive choice for a variety of applications:

1. Core Material: At the heart of decorative PU wall sandwich panels lies a core material made of polyurethane foam. This material is prized for its exceptional thermal insulation properties, helping to maintain comfortable indoor temperatures while reducing energy consumption. Additionally, polyurethane foam provides sound insulation, minimizing noise transmission and creating quieter indoor environments.

2. Exterior Finish: The exterior surface of decorative metal siding panels is adorned with a variety of finishes, ranging from sleek metallic coatings to textured patterns and vibrant colors. This versatility allows architects and designers to achieve their desired aesthetic vision, whether it be modern and minimalist or ornate and intricate.

3. Panel Dimensions: Decorative PU wall sandwich panels come in a range of dimensions to suit different project requirements. Standard panel widths are 383mm and 400mm, with lengths customizable to fit specific building dimensions. The thickness of the panels can vary as well, with options typically ranging from 10mm to 25mm, providing flexibility in insulation and structural performance.

4. Lightweight Construction: Despite their robust insulation properties, decorative PU wall sandwich panels are remarkably lightweight. This characteristic facilitates easy handling and installation, reducing labor costs and construction time. The lightweight nature of the panels also places less stress on building structures, making them suitable for both new construction and retrofit projects.

5. Fire Resistance and Durability: Decorative PU wall sandwich panels are engineered to meet stringent fire safety standards, ensuring the protection of occupants and assets. Additionally, these panels are highly durable, capable of withstanding environmental factors such as moisture, UV exposure, and temperature fluctuations. This durability contributes to the longevity of buildings and reduces maintenance requirements over time.

In summary, decorative PU wall sandwich panels offer a combination of thermal insulation, aesthetic appeal, ease of installation, and durability, making them a versatile choice for a wide range of construction projects across residential, commercial, and industrial sectors.